ABOUT : CAPITAL ENGRAVING

CAPITAL ENGRAVING is a modern & well-established firm located at Vadsar, Ahmedabad, Gujarat. Through personal & professional service, CAPITAL ENGRAVING is the most technically advanced gravure cylinder manufacturer which gives our customer consistency with excellent product quality. CAPITAL ENGRAVING has ensured that the finest print rollers are available globally, affordably and backed up by fast and reliable service. We have a very skilled, experienced, motivated & dedicated team which is the key to success in the fast paced and demanding manufacturing industry that we belong to.

MISSION

We endeavor to be the global leader in the gravure industry with brands built on a passion for creative craftmanship and superlative servicing presence.VISION

To be a Company that our Shareholders, Customers, Industry and Society want.-

CORE COMPETENCIES

15years of

PRE-PRESS EXPERIENCED TEAM18years of

TECHNICALLY EXPERIENCED TEAM

The requirements of our customers are defined and communicated to all our employees. CAPITAL ENGRAVING only provides products that meet it's customer's precise specifications. We follow PDCA (Plan, Do, Check, Act) cycle for quality excellence of each station of engraved cylinders like:

- Centralized communication system.

- Daily analysis of electroplating baths for Nickel, Copper and Chrome, accurately checking copper & chrome hardness of each cylinder.

- Cell geometry (Cell width/Cell wall/Depth) for each cylinder is checked to ensure correct reproducibility and consistency.

- Meticulous checking and matching of each cylinder proof with the master sample/artwork-prior to dispatch.

- Appropriate packing of cylinders is carried out to avoid any damage while in transit.

PRODUCTION PROCESS

1. Graphics Reproduction

2. Copper Plating

3. Polishing & Finishing

4. Engraving Process

5. Chrome Plating

6. Proofing

7. Quality assurance

8. PACKAGING FOR DELIVERY

PRODUCTS

With our world class production unit we produce

Gravure printing cylinder Specialized coating cylinder Decorative cylinder

Embossing cylinder Leather embossing cylinder De metalize (window) cylinder

OUR CLIENTS

APPLICATION

Flexible Packaging

Wooden Laminates

Design Wallpapers, Gift Wrappers

CONTACT US

- 792, Vadasar Bhoyan Road, Opp. TATA Heaven, Vadasar, Ahmedabad, Gujarat, India – 382721

- info: marketing@capitalengraving.in

- graphics@capitalengraving.in

- +91 9687825414

PRODUCTION PROCESS

-

1. Graphics Reproduction

In house pre-press department uses a specified packaging and planning software like Artpro, Pac Zed, High Quality Hinting Pro (HQH Pro), color management software & tools like high resolution graphics displays & printer technology assist by Apple, Epson to meet gravure printing requirements. The designer performs tests like color separation, resolution, auto trapping & bar code generation. Highly experienced and industry professional spin their magic on color calibrated monitors for optimum halftone result. The design is then physically checked with the digital proof and assured by the pre-press head for production.

-

2. Copper Platting

Our partner engineering company has the capabilities to manufacture steel cylinder bases. The base rotates in a bath or tank filled with a copper sulphate solution. Depending on the special requirements of the gravure cylinder, electro-mechanical surface treatment completes the preparation of the base which improves engraving quality of the cylinders.

-

3. Polishing & Finishing

The copper-finished cylinder then goes through a process of polishing and finishing to achieve the required size in preparation for engraving. Our ACIGRAF (Italy) Super Prefast Machine prepares optimal quality copper surface balance to minimize the tolerance and achieve evenness of the cylinder.

-

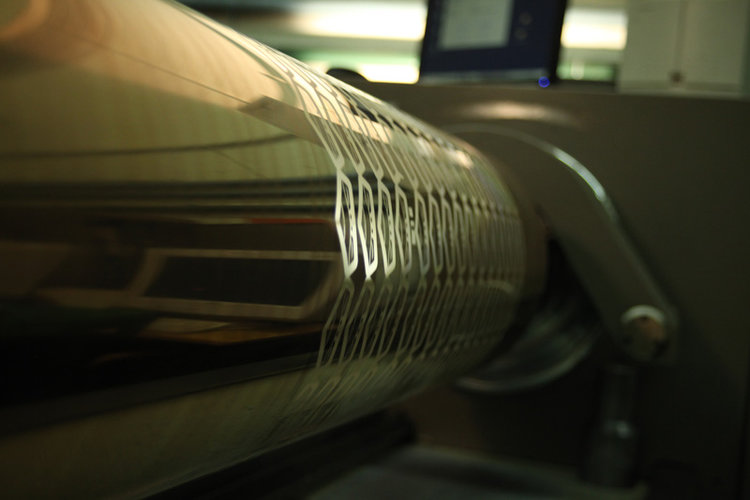

4. Engraving Process

The cylinder rotates in HelioKlischograph K5 Engraving Machine, which can provide HelioSprint BC+ to process through high quality detailing and counter sharpness. This state of the art machine can support speeds up to 9 kHz. The motorized support with integrated autofocus camera facilitates semi-automatic cell measurement.

-

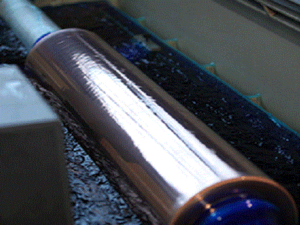

5. Chrome Plating

The cylinder surface is then chrome plated in a chrome bath, which has the identical appearance to that of a copper bath and finished (polished) immediately after the cylinder has been engraved for long life of cylinders.

-

6. Proofing

A technical content verification of the cylinder is then carried out via a proof press, which mimics the actual gravure printing press where quality officer assures colors and design.

-

7. Quality assurance

There are quality checks and balances in place at the end of each stage in the cylinder manufacturing process to eliminate errors with the final step encompassing a thorough inspection of the finished cylinder.

-

8. PACKAGING FOR DELIVERY

The cylinder is then carefully packaged using protective packaging material before it’s placed into a wooden box in preparation for dispatch to the customer for use.